#WeLoveSimulation

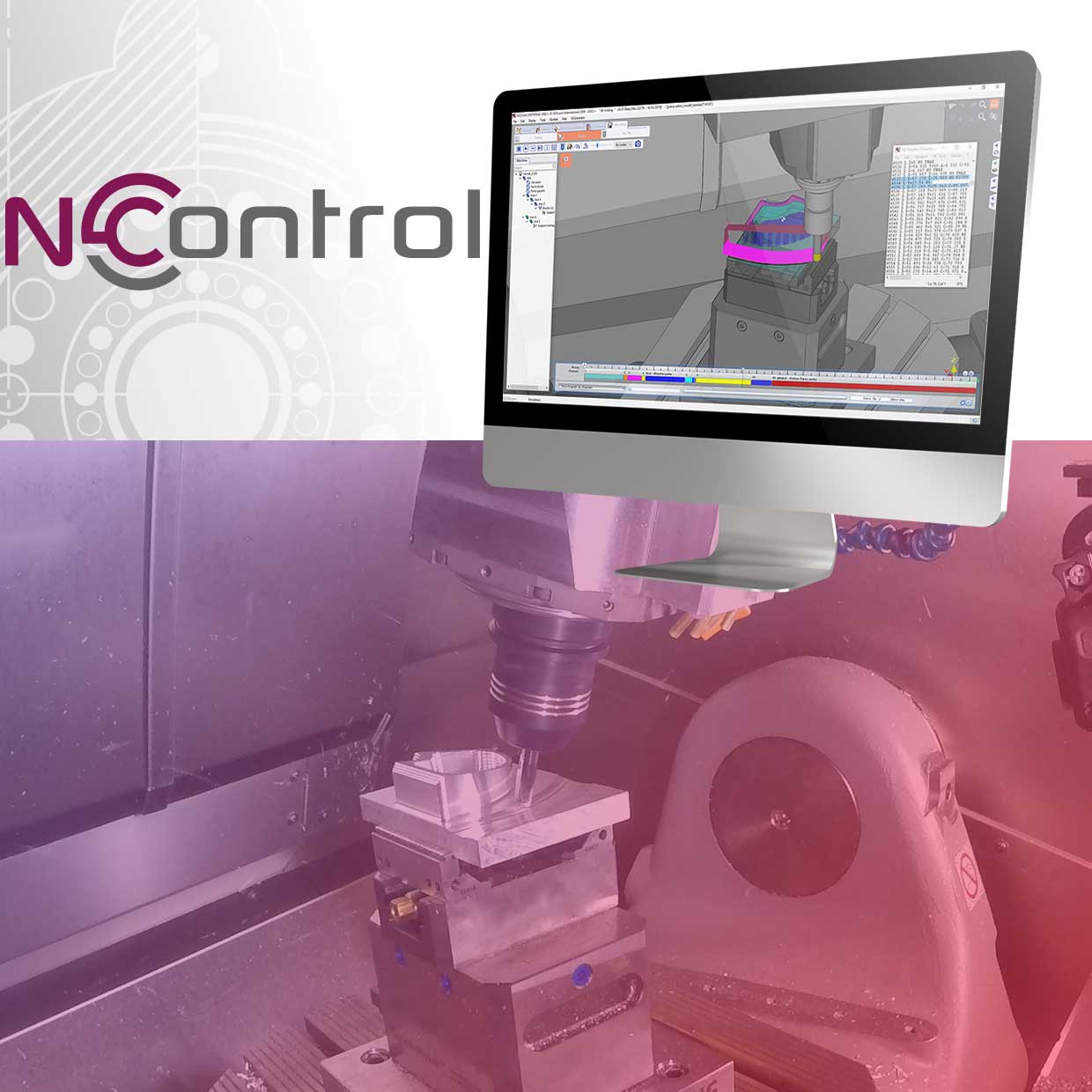

NC Control, a real NC Code verification inside GO2cam MTE, was made affordable, easy, accurate and rapid.

Unlike most CAM software, where toolpath/machine simulation is done before Post Processing and output of the NC Code, GO2cam MTE simulation is linked to the Post Processor. Modifying the Post Processor will result in a different machine simulation for inter-cycle movements. And more, if the user wants to validate the integrity of the NC Code, he needs to export datas (machine, tools, nc file…) to a 3rd party NC Verification software (which, by itself, expects more spendings on time and money).

We are now introducing NC Control: GO2cam MTE employs an integrated 3rd party verification algorithm to simulate real NC Code using the NC Controller cycles.

For more information please visit GO2cam. Klick here to enter the page.

With no transfer of files or any additional external software, NC Control in GO2cam is:

- Cost effective,

- No need for another software (installation, training, update…),

- More accurate: no transfer of stock, finish part, tooling…,

- No need to define 2 machines: one in CAM software and one in the verification software,

- Rapid: check the NC Code immediately and modify toolpath if needed,

- Available for most of NC controllers (Siemens, Heidenhain, Mazak, Haas, Fanuc, …),

- Flexibility: manual modification of NC file and immediate control possible.

Therefore, the movements of the machine in MTE are the same as the real movements of the machine. NC Control guarantees a reliable collision check based on the NC Code more efficient and much more accurate.